History

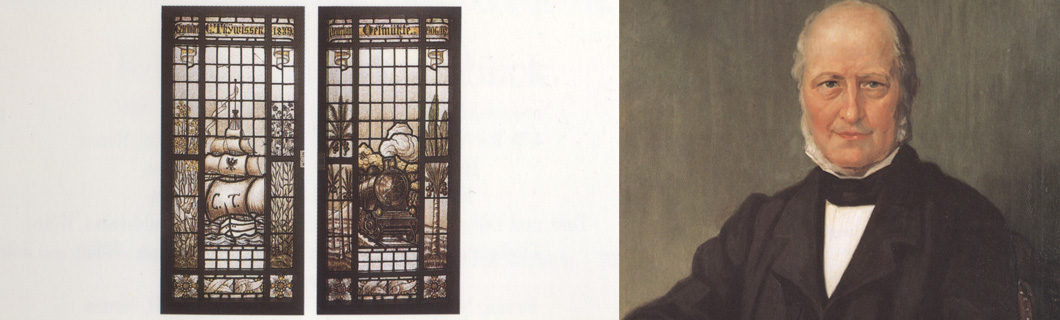

1 July 1839: "I have the honour of announcing to you that I have today founded my own oil trading and oil mill company at this very place."

Here Caspar Thywissen laid the foundation for the company which still today, in its sixth generation, is owned by the Thywissen family. Even then, the production of food products and trade in food products was a tradition in the family. Caspar Thywissen had only separated himself for business purposes from his brothers who had been operating various businesses of this kind in Neuss, Cologne and Aachen for four decades.

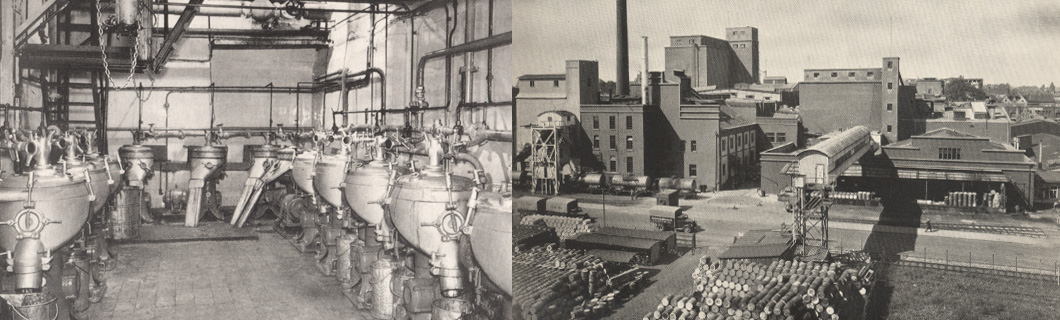

Thanks to the early use of steam engine technology and hydraulic presses, the first of their kind in Germany, the craft-based company very soon developed into industrial production. The geographical location of Neuss on the Rhine made it possible to ship different oilseeds from Europe and overseas, enabling the oil mill to expand steadily up to the present day.

In 1848, Caspar Thywissen moved to Cologne and engaged in soap production, oil trading and candlemaking on Eigelstein, established an oil refinery and traded in oil and grease. In this way, the family continued to expand its entrepreneurial activities.

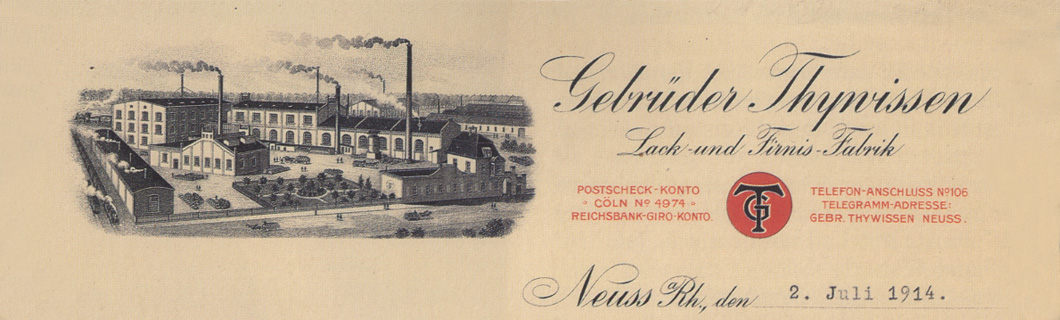

A lacquer and varnish factory, malt companies were acquired as well as interests in other companies in the Rhineland, such interests still being held today. A biodiesel factory was established in cooperation in Marl in 2002 and an oil mill with connected biodiesel plant in Verdun (France) in 2009, both of which fit the following strategy exactly:

To strengthen existing plants by expanding production in the same or closely related industries.

The merger of Schill Malz with the malting division of C.Thywissen GmbH into GlobalMalt in 2006 resulted in GlobalMalt becoming market leader in the industry in Germany and enabling it to further expand its global position. The sale of the malt production in 2011 was a strategic decision as a consequence of worldwide consolidation on the beer market.